Contact

Electrolux

= Heating Elements =

E-mail: electrolux@t-home.mk

E-mail: natasa@electrolux.mk

Telephone-Bitola: +389 (0) 47 203 330

Telephone-Skopje: +389 02 3298 130

Fax: +389 (0) 47 203 900

Mobile Phone Number: +389 (0) 70 237 108

![]()

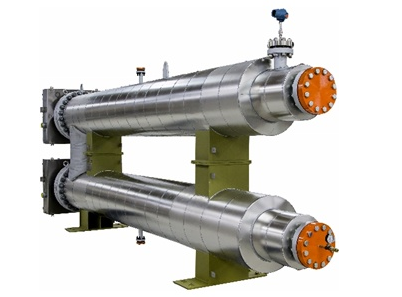

Random products

©2024 Electric Heating Elements | Designed by Electrolux Design Lab